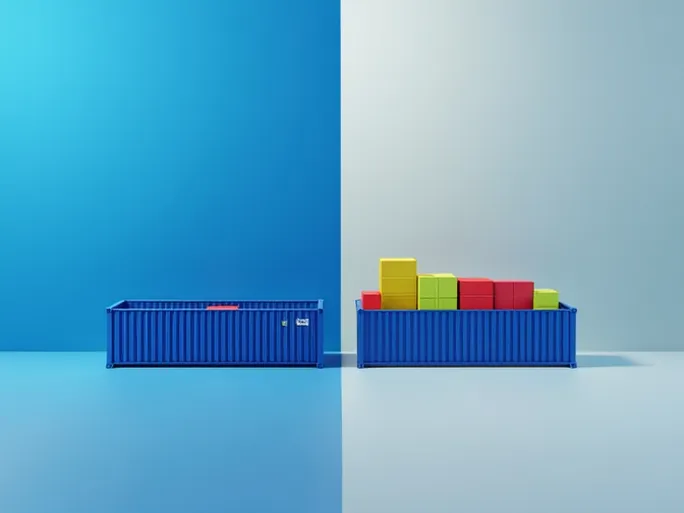

Imagine you're the logistics manager for a fast-growing e-commerce company, tasked with shipping electronics from China to the United States. Your choice between exclusive container use or shared space shipping directly impacts costs, delivery times, and potential cargo damage risks. Understanding the critical differences between Full Container Load (FCL) and Less than Container Load (LCL) shipping is essential for optimizing international freight strategies.

1. Full Container Load (FCL): Exclusive Space, Complete Control

Full Container Load (FCL) refers to a single shipper utilizing an entire container for their goods. This exclusive arrangement provides complete control over loading, packing, and securing methods. FCL is ideal when:

- Volume is sufficient: Your shipment nearly or completely fills a container

- Control is critical: You require specialized loading methods or extra protection

- Time sensitivity matters: FCL typically offers faster transit by eliminating consolidation steps

FCL advantages include enhanced cargo security, faster shipping times, and complete loading autonomy. However, choosing FCL for partial container loads may result in wasted space and higher costs.

2. Less than Container Load (LCL): Flexible, Cost-Effective Shipping

Less than Container Load (LCL) involves multiple shippers sharing container space, with costs calculated based on actual volume used. LCL makes sense when:

- Shipments are smaller: Your goods don't fill a full container

- Budget is limited: LCL typically costs less as you pay only for space used

- Timing is flexible: You can accommodate longer transit times for consolidation

While LCL reduces costs for smaller shipments, potential drawbacks include increased handling risks during consolidation/deconsolidation and extended delivery timelines.

3. Cost Structure Analysis: FCL vs. LCL

Understanding cost components helps make economical shipping decisions:

FCL Costs:

- Ocean freight: Whole-container rate (by container size)

- Port charges: Terminal handling, congestion fees

- Bill of lading fees

- Potential surcharges: Fuel adjustments, currency factors

LCL Costs:

- Ocean freight: Volume (CBM) or weight-based pricing

- Warehousing: Consolidation/deconsolidation storage

- Handling charges: Warehouse-container transfers

- Tallying fees: Cargo verification and sorting

- Documentation and customs clearance fees

The cost crossover point where FCL becomes economical varies by route, commodity type, and market conditions. Detailed quotes from freight forwarders enable accurate comparisons.

4. Customs Clearance Comparison

FCL's single-shipper nature simplifies customs processing with unified documentation. LCL requires individual clearance for each consignment within the container, potentially extending processing times. Additional considerations:

- Document preparation: Complete commercial invoices, packing lists, and bills of lading in advance

- Accurate declarations: Prevent delays or penalties from incorrect information

- Experienced brokers: Qualified customs brokers streamline clearance processes

5. Risk Assessment and Mitigation

FCL primarily risks container-level damage or loss during transit. LCL introduces additional handling exposures during consolidation/deconsolidation, plus potential cargo mixing errors. Risk reduction strategies include:

- Cargo insurance: Financial protection against damage or loss

- Reputable forwarders: Established providers with robust procedures

- Enhanced packaging: Protective measures for handling and transit

The optimal choice depends on specific operational requirements. FCL suits high-volume, time-sensitive shipments needing loading control, while LCL benefits smaller, budget-conscious shipments with flexible timelines. Comprehensive cost-benefit analysis and risk evaluation ensure informed shipping decisions that optimize supply chain performance.