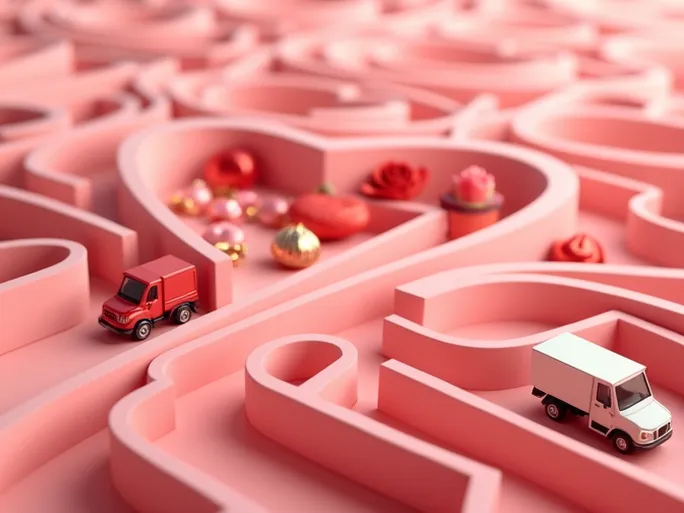

Valentine's Day, a holiday brimming with affection and consumer impulse, might appear as simply another occasion for purchasing flowers and chocolates to the average shopper. Behind the retail scenes, however, it represents one of the most rigorous tests of supply chain management capabilities.

The Unique Challenges of Valentine's Day Supply Chains

As a quintessential seasonal event, Valentine's Day presents several distinctive supply chain management challenges:

- Volatile demand: The holiday creates dramatic spikes in demand for flowers, chocolates, and gifts, requiring precise forecasting and inventory management.

- Compressed timeline: The entire sales cycle typically concentrates within a few days before February 14th, demanding exceptional operational efficiency.

- Product diversity: Valentine-related merchandise spans multiple categories—from perishable flowers to packaged chocolates—each requiring specialized handling.

- Elevated expectations: Consumers associate purchases with emotional significance, intensifying quality and service requirements.

Strategic Approaches to Seasonal Supply Chain Management

Retailers employ several key strategies to navigate these seasonal challenges:

Advanced Demand Forecasting

Sophisticated predictive models incorporating historical sales data, market trends, and promotional impacts help anticipate demand fluctuations. Machine learning algorithms increasingly account for external variables like weather patterns and competitive actions.

Agile Network Design

Leading organizations implement flexible supply chain architectures that combine responsive and agile approaches. Backup suppliers and alternative transportation routes provide resilience against disruptions.

Dynamic Inventory Optimization

Balancing economic order quantities with safety stock requirements becomes critical during demand surges. Real-time inventory monitoring helps identify slow-moving products before they become liabilities.

Cross-Functional Coordination

Sales and operations planning (S&OP) processes synchronize activities across procurement, logistics, and merchandising teams. Weekly—sometimes daily—alignment meetings become essential during peak periods.

Technology Integration

IoT sensors track shipments in transit, while AI-powered analytics optimize warehouse operations. Some retailers now incorporate social media sentiment analysis into their forecasting models.

Case Study: Albertsons' Valentine's Day Preparation

Bryan Verbarendse, a distribution executive at Albertsons supermarkets, oversees product flows from three distribution centers to approximately 200 stores across the American Southwest. His experience highlights several best practices:

- Implementing air freight solutions to accelerate floral deliveries

- Initiating planning sessions months in advance with marketing teams

- Developing contingency plans for weather-related disruptions

- Experimenting with machine learning to refine demand predictions

The Fundamentals of Effective Supply Chain Design

Successful seasonal supply chains share several core attributes:

- Strategic alignment: Operations must support broader business objectives, whether prioritizing cost efficiency or premium service.

- Customer-centricity: Network configurations should reflect shopper expectations regarding speed, variety, and availability.

- Risk mitigation: Geographic diversification, secondary suppliers, and insurance protections guard against disruptions.

- Sustainability: Environmentally responsible sourcing and distribution methods increasingly influence design decisions.

Overcoming Forecasting Obstacles

Despite technological advances, predicting Valentine's demand remains imperfect. Retailers combat common forecasting pitfalls through:

- Data quality initiatives that cleanse historical records

- Model selection processes matching algorithms to product characteristics

- Continuous monitoring of prediction accuracy metrics

- Cross-departmental review mechanisms to identify systemic biases

The Critical Role of Supply Chain Collaboration

Information sharing between retailers, suppliers, and logistics providers yields significant benefits:

- 15-30% reductions in inventory carrying costs through coordinated planning

- 20% improvement in forecast accuracy from shared data insights

- Enhanced responsiveness to unexpected demand shifts

Managing Seasonal Supply Chain Risks

Valentine's Day amplifies four primary risk categories:

| Risk Type | Mitigation Strategy |

|---|---|

| Supplier failures | Pre-qualified alternate vendors |

| Transportation delays | Multi-modal shipping options |

| Demand volatility | Dynamic pricing algorithms |

| Operational disruptions | Redundant IT systems |

Conclusion

Seasonal events like Valentine's Day present both extraordinary challenges and opportunities for supply chain innovation. Retailers that master demand prediction, network flexibility, and cross-enterprise collaboration gain competitive advantages that extend far beyond February 14th. As consumer expectations continue rising and market conditions grow more volatile, these capabilities will separate industry leaders from the rest.