In the vast ocean of international trade, shipping containers serve as steel giants carrying goods across continents. The efficient and safe loading of these containers is a sophisticated discipline that directly impacts transportation costs, cargo safety, and overall logistics efficiency. Particularly when handling mixed cargo loads, improper loading can lead to damaged goods, delivery delays, and even legal disputes.

Container Types: Selecting the Right Vessel

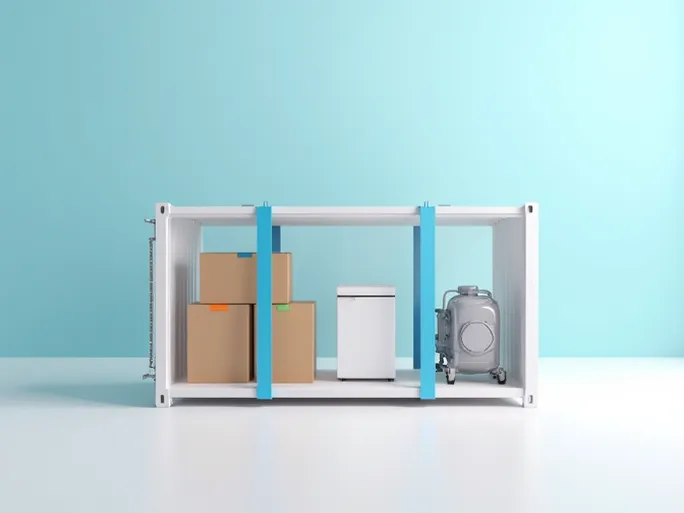

International shipping offers various container options, including dry containers, refrigerated containers, open-top containers, and flat rack containers. Dry containers remain the most widely used type, suitable for transporting electronics, textiles, and other general merchandise. Standard sizes include 20-foot (33 cubic meters capacity) and 40-foot (67 cubic meters) variants, with high-cube 40-foot containers offering 76 cubic meters of space.

Refrigerated containers maintain temperature-controlled environments for perishables like food and pharmaceuticals. Open-top containers accommodate oversized or irregularly shaped cargo with top-loading access, while flat racks specialize in transporting heavy machinery and oversized equipment.

Pre-Loading Preparation: The Foundation of Success

Thorough preparation before loading ensures operational efficiency and cargo safety through three critical steps:

- Cargo Inspection: Verify quantities, specifications, and packaging against packing lists while examining for damage or defects. Reinforce fragile packaging with additional padding or palletization.

- Container Inspection: Examine container integrity including walls, flooring, door seals, and cleanliness. For reefer containers, confirm proper refrigeration functionality.

- Loading Plan Development: Create detailed stowage plans considering cargo characteristics and container dimensions, prioritizing weight distribution and compatibility.

Loading Procedures: Precision and Safety

The loading process requires methodical execution following these principles:

- Space Optimization: Maximize container utilization through tight stacking patterns, using void fillers for irregular shapes while maintaining balanced weight distribution.

- Cargo Securement: Prevent transit movement using straps, ropes, dunnage, or plywood partitions. Specialized equipment may require vibration-dampening solutions.

- Documentation: Maintain comprehensive loading records including photographs, cargo positions, and condition reports for reference during transit and customs clearance.

Mixed Cargo Considerations: Managing Compatibility

Combining different commodities in single containers presents unique challenges requiring attention to:

- Chemical Compatibility: Avoid mixing odor-emitting, dust-producing, or reactive substances with sensitive goods (e.g., keeping spices separate from tea leaves).

- Packaging Variations: Implement protective barriers between differently packaged items to prevent crushing or abrasion damage.

- Handling Requirements: Group cargo with similar loading/unloading methods to streamline operations and minimize handling risks.

- Customs Compliance: Clearly segregate and document goods with different HS codes, tariff rates, or regulatory requirements to facilitate clearance.

Cost and Transit Time Factors

Shipping expenses and delivery timelines fluctuate based on trade routes, seasonal demand, commodity types, container specifications, and fuel surcharges. Representative benchmarks include:

- China to U.S. West Coast: $1,000-$3,000 for 20' dry containers with 13-20 day transit

- China to European Base Ports: $1,500-$4,000 for 20' dry containers with 25-35 day transit

These estimates serve as general references, with actual rates subject to market conditions and specific shipment parameters.

Conclusion: Strategic Loading for Competitive Advantage

Mastering container loading techniques—particularly for mixed cargo—represents a critical competency in global trade operations. From meticulous preparation to execution and compliance management, each phase contributes to transportation safety, cost efficiency, and supply chain reliability. By implementing these professional loading practices, businesses can enhance their logistical competitiveness while delivering goods securely to international markets.