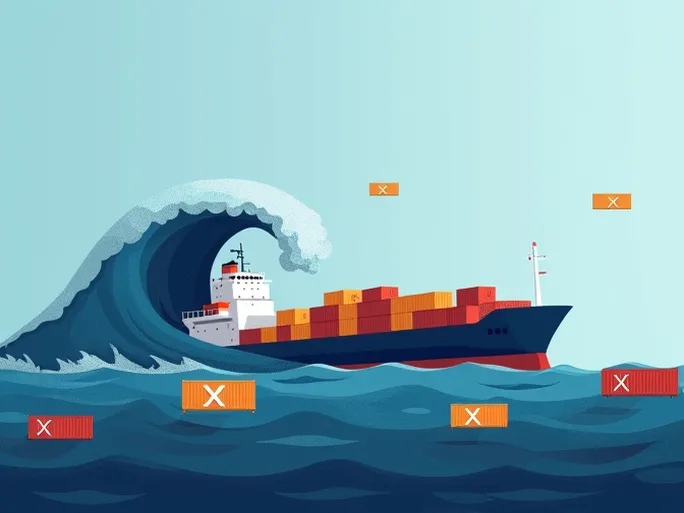

Just as goods are about to reach their destination and customers eagerly await delivery, unexpected shipping disruptions can create logistical nightmares. From rolled cargo to port skipping and delays, these challenges can test even the most experienced importers and exporters. This comprehensive guide examines three common ocean freight disruptions and provides actionable solutions to minimize losses.

1. Rolled Cargo: When Your Shipment Gets Bumped

Imagine preparing goods for shipment only to receive last-minute notification that your container won't be loaded due to "no available space." This frustrating scenario, known as rolled cargo, forces shipments to wait for the next available vessel.

Understanding the Causes:

- Overbooking practices: During peak seasons, carriers frequently oversell capacity by 20-30% to maximize profits, leaving lower-priority shipments vulnerable to being bumped.

- Operational delays: Missed cut-off times, customs clearance issues, or port congestion can prevent timely loading.

- Unforeseen circumstances: Draft restrictions, severe weather, or other emergencies may force vessels to reduce loads.

Proactive Solutions:

- Early booking: Secure space 3-4 weeks in advance and negotiate guaranteed allocation agreements with carriers.

- Direct routing: Prioritize direct services with major carriers to minimize transshipment risks.

- Precision timing: Strictly adhere to all deadlines for packing, customs clearance, and container return.

- Damage control: If rolled, immediately request rebooking on the next available vessel while negotiating detention fee waivers and maintaining transparent customer communication.

2. Port Skipping: When Vessels Change Course

Port skipping occurs when carriers unexpectedly omit scheduled port calls, disrupting carefully planned logistics chains.

Primary Reasons for Omissions:

- Port congestion: Labor strikes, equipment shortages, or operational bottlenecks may make certain ports impractical.

- Route optimization: Carriers may adjust schedules to improve efficiency and reduce costs.

- Safety concerns: Adverse weather or security issues can necessitate last-minute changes.

Contingency Planning:

- Real-time tracking: Monitor vessel movements continuously and verify revised port calls immediately.

- Alternative arrangements: Coordinate with local agents to organize feeder vessel or trucking solutions to original destinations.

- Compensation claims: Document all carrier notifications and pursue appropriate adjustments or refunds while updating clearance schedules.

3. Shipping Delays: Managing Late Arrivals

Extended Estimated Time of Arrival (ETA) fluctuations can significantly impact inventory planning and customer commitments.

Common Delay Factors:

- Port inefficiencies: Slow turnaround times and equipment shortages prolong vessel stays.

- Natural obstacles: Typhoons, piracy threats, or other hazards affect sailing speeds.

- Technical issues: Mechanical failures, provisioning delays, or route changes disrupt schedules.

Mitigation Strategies:

- Advanced monitoring: Track Actual Time of Departure (ATD) and Arrival (ATA) through carrier systems to anticipate delays.

- Proactive communication: Notify consignees promptly about revised timelines to prevent contractual issues.

- Risk management: Consider delay insurance or emergency air freight for time-sensitive, high-value shipments.

4. Universal Prevention Strategies

- Reputable partnerships: Work with top-tier carriers and freight forwarders known for reliable capacity.

- Buffer planning: Build 7-10 extra days into delivery schedules to accommodate potential disruptions.

- Continuous visibility: Implement daily shipment tracking to identify and address issues early.

By implementing these strategies, businesses can navigate ocean freight challenges effectively, transforming potential crises into manageable situations while protecting supply chain integrity.