Are you focusing solely on visible transportation costs while overlooking the hidden losses caused by supply chain damage? Imagine a single instance of damaged goods—not just a logistics headache, but a domino effect that reverberates across your entire organization, ultimately eroding profit margins.

Breaking Departmental Silos: The Ripple Effect of Supply Chain Damage

Traditional thinking suggests that if each department operates efficiently, overall performance will improve. However, this compartmentalized approach often ignores the interconnected nature of modern business operations. Supply chain damage exemplifies this blind spot.

When products are damaged during transit, the immediate impact falls on logistics teams handling claims and replacements. But the consequences extend far beyond:

- Sales team frustration: Delayed deliveries or defective products lead to plummeting customer satisfaction, lost sales opportunities, and brand reputation damage.

- Marketing challenges: Promised product quality fails to materialize, undermining marketing campaigns and potentially requiring costly crisis management.

- Financial pressures: Beyond direct replacement costs, companies face additional expenses including administrative overhead, customer compensation, and potential legal liabilities.

- Production disruptions: Returns and replacement demands disrupt manufacturing schedules, reduce efficiency, and complicate inventory management.

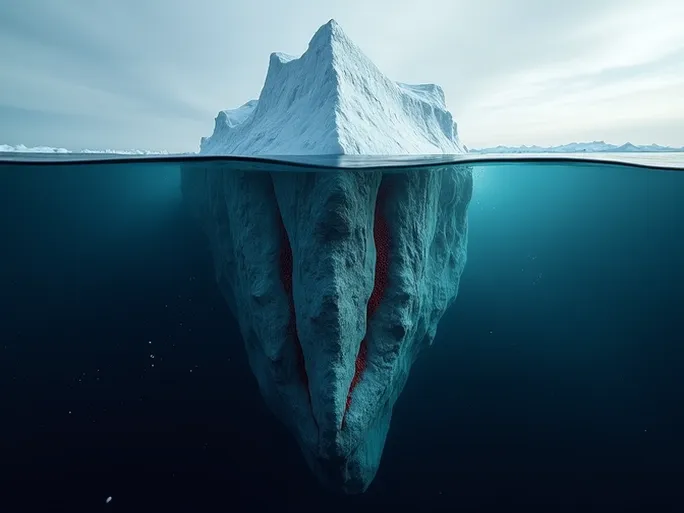

The Cost Iceberg: Seeing Beyond Surface-Level Expenses

Most businesses track only the direct costs of supply chain damage—repairs, replacements, and transportation fees. These represent merely the tip of the iceberg. The true financial impact lies beneath the surface:

- Opportunity costs: Missed sales and potential customers due to delays or quality issues.

- Brand equity erosion: Diminished consumer trust and negative word-of-mouth that degrades long-term brand value.

- Customer retention expenses: Increased resources required to manage complaints, returns, and potential client attrition.

- Administrative burdens: Time-consuming claim processing, interdepartmental coordination, and dispute resolution.

From Reactive to Proactive: Building End-to-End Damage Prevention

Rather than scrambling to address damage after it occurs, forward-thinking organizations implement comprehensive prevention strategies across the supply chain:

- Enhanced packaging: Durable, customized packaging solutions tailored to product specifications and transportation hazards.

- Transportation oversight: Partnering with reliable logistics providers, optimizing routes, and implementing real-time shipment monitoring.

- Handling protocols: Comprehensive training programs for warehouse and loading personnel to minimize human error.

- Warehouse optimization: Climate-controlled storage facilities and advanced equipment to prevent environmental damage.

- Predictive analytics: Data-driven identification of vulnerable supply chain nodes with preemptive mitigation measures.

Cross-Functional Collaboration: Breaking Down Organizational Barriers

Effective damage reduction requires dismantling departmental silos through coordinated initiatives:

- Interdepartmental task forces: Regular meetings to share intelligence and align damage prevention efforts.

- Shared performance metrics: Incorporating supply chain integrity into departmental KPIs to incentivize participation.

- Centralized data platforms: Unified systems providing visibility across all supply chain touchpoints.

- Streamlined communication: Clear protocols for rapid information sharing during disruptions.

The Strategic Dividend: Benefits Beyond Cost Reduction

Investing in supply chain protection delivers measurable competitive advantages:

- Enhanced customer loyalty: Consistent delivery of undamaged products builds consumer confidence.

- Brand differentiation: Superior product condition becomes a marketable quality differentiator.

- Operational efficiency: Reduced returns enable leaner production scheduling and inventory control.

- Risk mitigation: Decreased exposure to legal and financial contingencies.

- Workforce morale: Elimination of preventable operational headaches improves employee satisfaction.

Supply chain damage need not remain an invisible profit drain. By implementing comprehensive prevention systems, organizations can unlock their supply chain's full potential.