In the fast-paced world of air cargo transportation, efficiency, cost control and reliability are critical factors for airlines, ULD (Unit Load Device) leasing companies and MRO (Maintenance, Repair and Overhaul) providers. Traditional ULD maintenance models often face significant challenges, particularly when localized damage to pallet seat rails requires complete base structure replacement, leading to prolonged downtime and exorbitant repair costs.

The Challenges of Conventional ULD Maintenance

ULD components serve as essential infrastructure for safely and efficiently loading cargo onto aircraft. However, these units inevitably sustain damage from various factors including handling impacts, extreme weather conditions and general wear from prolonged use.

Standard maintenance procedures typically involve complete replacements or extensive repairs. When base structures, particularly seat rails, become damaged, the conventional approach requires:

- Disassembling damaged base profiles, often involving numerous rivets or fasteners

- Preparing replacement components through cutting, drilling and finishing

- Reinstalling new base structures with proper fastening

- Conducting post-repair safety inspections

This labor-intensive process can consume hours or even days, creating operational bottlenecks for time-sensitive cargo operations. Additionally, complete base replacements generate substantial material waste, increasing both environmental impact and disposal costs.

Innovative Design Delivers Unprecedented Efficiency

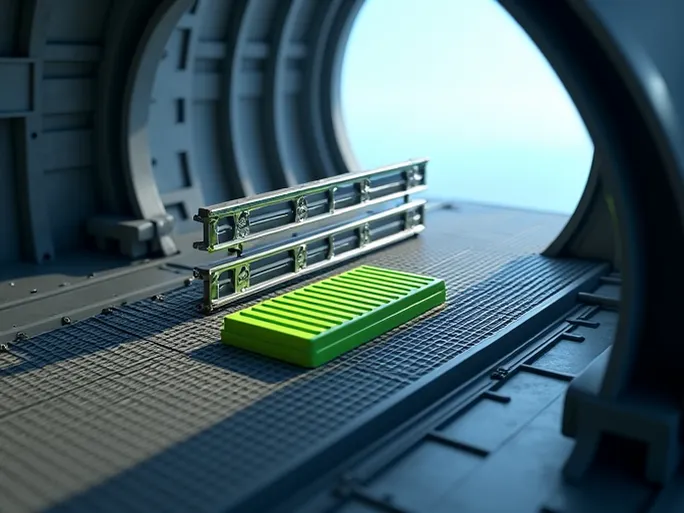

AeroNet's ETSO C90d-certified detachable seat rail system represents a paradigm shift in ULD maintenance. The modular design allows individual rail components to be replaced without disturbing the base structure, offering multiple advantages:

- Rapid repairs: Damaged rails can be swapped in minutes rather than hours

- Cost reduction: Targeted component replacement slashes material and labor expenses

- Operational continuity: Minimized downtime maintains cargo throughput

- Inventory optimization: Reduced spare parts requirements simplify logistics

The most dramatic improvement comes in repair speed. Where traditional base replacements required 45 minutes, AeroNet's system enables complete rail swaps in just five minutes by removing only three rivets - a ninefold efficiency gain that significantly improves turnaround times.

Engineering Excellence in Every Detail

AeroNet's design philosophy extends to corner connection points, where conventional methods necessitated removing multiple fasteners from both flooring and structural profiles. The innovative solution uses a single-screw mechanism that dramatically simplifies the process while reducing physical strain on maintenance crews.

Standardized 330mm (13-inch) rail components optimize logistics by minimizing shipping volume and storage requirements compared to full base structures. The compact design translates to direct savings in transportation and warehousing costs.

Manufactured from high-strength materials, the detachable rails withstand rigorous operating conditions while maintaining long-term durability. The system's robust construction ensures reliable performance throughout extended service life.

Transforming ULD Maintenance Economics

Beyond immediate operational benefits, AeroNet's innovation promises to reshape maintenance economics across the air cargo industry. Airlines stand to reduce equipment downtime while improving asset utilization. Leasing companies gain enhanced fleet availability with lower maintenance overhead. MRO providers can offer more efficient service turnaround with reduced labor requirements.

The technology also aligns with sustainability initiatives by minimizing material waste and reducing the carbon footprint associated with transporting replacement components.

As the industry progresses toward digital transformation, such modular designs create opportunities for implementing predictive maintenance systems and advanced asset tracking technologies. The ability to quickly replace specific components rather than entire structures provides a foundation for more sophisticated maintenance strategies.