New Train Model Enhances Warehouse Efficiency

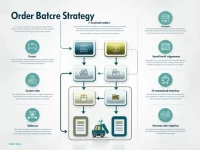

The train-based picking model, an innovative approach to order fulfillment, enhances efficiency by having one individual manage multiple compartments, addressing bottlenecks found in traditional picking methods. This model emphasizes pull-based operations to improve warehouse management efficiency, making it a worthy reference for more companies.