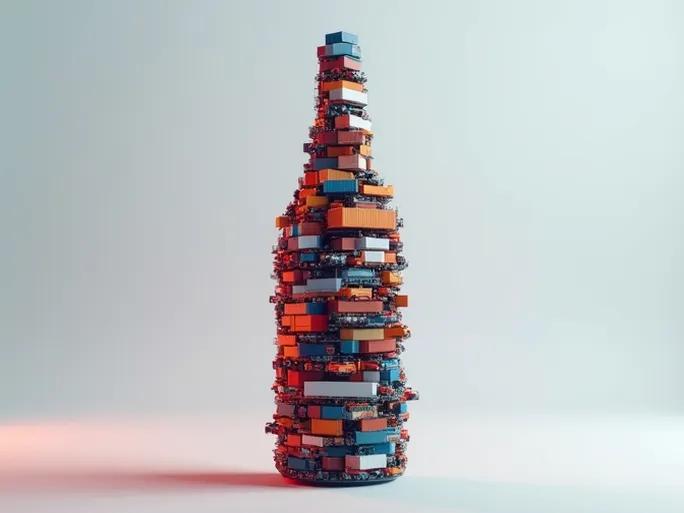

In today's volatile global economy, supply chain resilience has become a critical competitive differentiator. As the backbone of logistics networks, freight transportation's stability and efficiency directly impact corporate operational costs and market responsiveness. However, the industry currently faces unprecedented challenges—capacity shortages, rampant order rejections, and skyrocketing rates—creating immense pressure for shippers.

Chapter 1: Market Realities: The Capacity Crunch

1.1 The Great Imbalance: Soaring Demand Meets Limited Capacity

Global economic recovery has fueled explosive growth in freight demand. E-commerce expansion, manufacturing growth, and intensifying international trade all require more transportation resources. Yet capacity growth lags significantly behind demand due to multiple constraints:

- Persistent pandemic-induced supply chain disruptions

- Chronic port congestion and container shortages

- Insufficient transportation infrastructure investment

- Acute labor shortages across logistics sectors

1.2 The New Normal: Carriers' "Good Problem to Have"

Freight providers face a paradoxical situation—overwhelming order volumes but insufficient capacity to fulfill them. During peak seasons, rejection rates frequently exceed 30%. Three primary factors drive these decisions:

- Physical limitations: Finite truck and driver availability

- Profit optimization: Prioritizing high-margin shipments

- Risk management: Avoiding problematic loads

The privately-held Shevell Group, ranked #70 among U.S. freight companies with $439.5 million in revenue, exemplifies the industry's capacity constraints. CEO Myron P. "Mike" Shevell stated their business could double with adequate drivers. The company's mitigation strategies include:

- Enhanced driver compensation packages

- Advanced route optimization systems

- Preventive vehicle maintenance programs

- Strategic order selection

Chapter 2: Rate Escalation: Inevitable Market Correction

2.1 Pricing Fundamentals: Supply-Demand Economics

Persistent capacity shortages have cemented rate increases across all freight segments. Beyond basic market mechanics, multiple cost drivers push prices upward:

- Driver wages increasing 15-20% annually

- Volatile fuel prices adding 20-30% operational cost variability

- Equipment costs rising with emissions compliance requirements

- Insurance premiums growing 10-15% year-over-year

2.2 Future Outlook: Sustained Elevated Pricing

Industry analysts project continued rate growth due to:

- Structural driver shortages (estimated 80,000 deficit in U.S.)

- Tightening emissions regulations (EPA 2027 standards)

- Persistent fuel price volatility

- Broad inflationary pressures

August spot rates declined slightly from summer peaks but remain 20% above 2020 levels. Specialized segments show particular strength:

- Flatbed demand matching 2017 levels

- Refrigerated shipments surging in northern states

- Agricultural product transport at seasonal highs

Chapter 3: Root Causes: Cost Structures and Market Dynamics

3.1 The Cost Squeeze: Breaking Down Expense Components

Freight providers face compounding cost pressures:

| Cost Category | Annual Increase |

| Driver Compensation | 18-22% |

| Fuel | 25-40% |

| Equipment | 12-15% |

| Regulatory Compliance | 8-10% |

Chapter 4: Shipper Strategies: Adaptation and Innovation

4.1 Operational Optimization

Progressive shippers implement multifaceted approaches:

- Network redesign: Consolidating distribution centers

- Modal shifts: Increased intermodal utilization

- Load optimization: 5-15% efficiency gains

- Inventory management: Right-sizing safety stocks

E-commerce retailer: Achieved 12% last-mile cost reduction through AI-powered routing.

Manufacturer: Cut long-haul expenses 18% via rail-truck intermodal integration.

Consumer goods company: Secured capacity through strategic carrier partnerships.

Chapter 5: Industry Outlook: Transformation Ahead

5.1 Emerging Challenges

The sector confronts several structural issues:

- Demographic shifts reducing driver availability

- Accelerating decarbonization requirements

- Technology adoption gaps

5.2 Growth Opportunities

Counterbalancing forces create new potential:

- E-commerce growth requiring specialized logistics

- Nearshoring driving regional freight demand

- Emerging market infrastructure development

Conclusion: Navigating the New Normal

The freight market's fundamental restructuring requires strategic responses from all stakeholders. Shippers must embrace operational flexibility, carriers need to accelerate digital transformation, and policymakers should facilitate industry modernization. Those who adapt effectively will emerge stronger in this transformed logistics landscape.