The rapid growth of e-commerce has placed unprecedented demands on warehouse logistics. Picture a facility overflowing with packages awaiting shipment, exhausted workers struggling to keep pace, and orders continuing to pour in relentlessly. In this competitive landscape, how can businesses seize opportunities during peak seasons? The answer may lie in intelligent, automated warehouse upgrades.

Challenges in Modern Warehouse Logistics

The e-commerce boom presents both opportunities and significant operational hurdles:

- Safe Return-to-Work Protocols: Pandemic-related health concerns require substantial investments in safety measures and workflow redesign to maintain social distancing.

- Persistent Labor Shortages: Workforce scarcity and rising labor costs, exacerbated by global disruptions, make it increasingly difficult to meet surging order volumes.

- Escalating Consumer Expectations: Customers demand faster deliveries and seamless return processes, pressuring logistics operations to enhance efficiency.

- Multi-Market Peak Periods: Global e-commerce expansion creates overlapping demand spikes across regions, testing operational resilience.

Collaborative Robots: A Strategic Solution

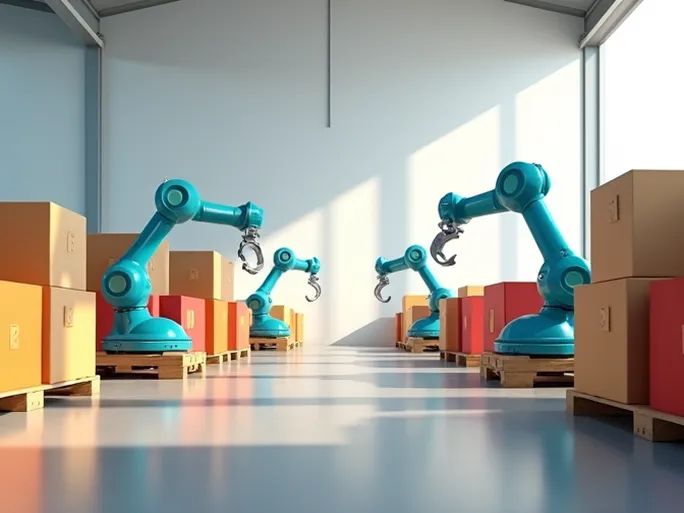

Traditional warehouse solutions often fall short against these challenges. Collaborative robots (cobots) offer distinct advantages:

- Enhanced Efficiency: Cobots handle repetitive tasks like picking and transporting goods, allowing human workers to focus on complex decision-making.

- Operational Flexibility: Scalable deployments adapt to fluctuating demand—increasing robot capacity during peaks and reducing it during slower periods.

- Improved Workplace Conditions: By assuming physically demanding tasks, cobots reduce worker fatigue and improve job satisfaction.

- Error Reduction: Programmed precision minimizes picking and shipping mistakes, decreasing returns and improving customer satisfaction.

Key Advantages of Cobot Technology

Several features make collaborative robots particularly suitable for warehouse environments:

- Rapid Deployment: Requires minimal infrastructure changes compared to traditional automation systems.

- Advanced Safety Features: Equipped with sensors to prevent collisions with human coworkers.

- Task Versatility: Capable of picking, packing, inventory management, and transportation with reprogrammable functionality.

- Scalable Architecture: Businesses can incrementally expand robot fleets as needs evolve.

Implementation Case Studies

Real-world applications demonstrate cobots' transformative potential:

- An e-commerce retailer achieved 50% faster order picking through automated navigation systems that locate and retrieve items.

- A logistics provider reduced material handling costs by 30% using cobots for continuous goods transportation.

- A retail chain shortened inventory audits by 80% with autonomous shelf-scanning robots.

Selecting the Right Cobot Solution

Businesses should evaluate these factors when implementing automation:

- Operational Requirements: Match robot capabilities to specific workflow needs (e.g., high-speed picking vs. heavy-load transportation).

- Performance Metrics: Assess payload capacity, movement speed, and positioning accuracy.

- Safety Compliance: Verify collision-avoidance systems and emergency stop mechanisms.

- Vendor Expertise: Partner with established providers offering comprehensive support and integration services.

The Future of Warehouse Automation

As technology advances, cobots will become standard in logistics operations. Future warehouses will likely integrate:

- Autonomous forklifts and transport vehicles

- AI-powered order optimization systems

- IoT-enabled real-time inventory tracking

This technological convergence promises to redefine warehouse efficiency, creating smarter, more responsive supply chains capable of meeting e-commerce's evolving demands.