In today's rapidly evolving retail landscape, efficiently and accurately meeting customer demands has become the ultimate competitive differentiator. For apparel customization giant Cutter & Buck, improving order picking efficiency isn't just about cost control—it directly impacts customer satisfaction and market competitiveness. But how did this company break through operational bottlenecks to achieve a quantum leap in fulfillment productivity?

The Pandemic Wake-Up Call

Headquartered in Seattle, Cutter & Buck is renowned for its active sportswear and lifestyle apparel. The company sells through multiple channels including direct-to-consumer, retail stores, and customized clothing orders. To serve the North American market, it operates three distribution centers, with its Renton, Washington facility specializing in customized apparel—equipped with state-of-the-art embroidery machines handling nearly 50% of the location's picking volume.

During the pandemic, Cutter & Buck's Washington distribution center faced unprecedented challenges. The collision of surging e-commerce orders with labor shortages made holiday peak periods particularly difficult to manage. The situation became so acute that C-suite executives including CFO and CEO Joel Peter Freet personally joined frontline teams in fulfilling orders from three-level picking modules.

"During holidays, we all participated—getting trained on picking processes and committing to multiple shifts weekly," Freet recalled. "By 2021 holidays, our e-commerce growth was so explosive we had no choice but to pitch in again. In our post-analysis, we realized we needed a productivity breakthrough to support future peak seasons—that's when we began seriously evaluating next-generation picking automation."

The Automation Solution

Scott Sampt, Cutter & Buck's Executive Director of Distribution, Enhancement and Logistics, explained that their Renton facility manages two distinct workflows: shipping non-customized apparel directly to consumers or retail partners, and ensuring embroidery production receives correct SKUs/sizes for customized orders. With the company priding itself on exceptional service levels and rapid turnaround times, the picking bottleneck demanded resolution.

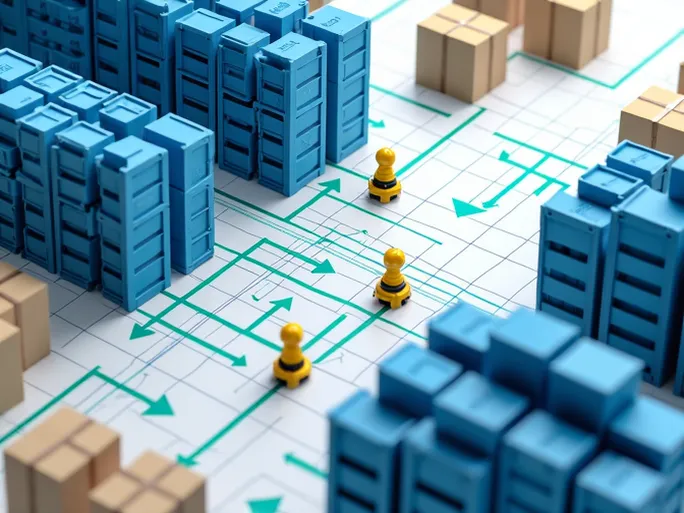

After evaluating alternatives including mobile robots, leadership settled on implementing a high-density robotic automated storage and retrieval system (AS/RS). The AutoStore solution—provided by Kardex as system integrator—went live in August 2023, operating on Kardex's FulfillX Warehouse Execution System (WES) software.

The implementation included integrating WES with Cutter & Buck's Manhattan Associates WMS using SVT Robotics' middleware to coordinate replenishment, order allocation, and picking processes.

Goods-to-Person Advantages

The AutoStore system revolutionized operations by implementing goods-to-person (GTP) principles. Where pickers previously walked between module levels to retrieve items, they now remain stationary at ports while robots retrieve bins from a dense storage grid. Visual light prompts and simple screen instructions make the system intuitive—new pickers become proficient within 10 minutes including safety protocols.

The Renton installation features 11 ports, 34,000 bin locations, and 54 robots—scalable for five years' growth through additional components. Direct-to-consumer orders are now picked directly into shipping cartons, while blank garments for embroidery are selected into totes and wheeled to nearby staging areas.

"AutoStore absolutely improved our picking efficiency," Sampt noted. "We consistently achieve same-day shipping for blank orders while reducing embroidery process time—the system rapidly delivers orders to either shipping or embroidery departments."

Operational Transformation

The implementation reduced peak-season picking staff from 30 to just 12 employees handling equivalent volumes. More importantly, it eliminated bottlenecks that previously constrained service levels. The three-day WIP storage area was repurposed into a mezzanine-level overflow space, while the former picking modules were replaced with very narrow aisle (VNA) storage for replenishment inventory.

Despite occupying slightly less square footage than the old picking modules, AutoStore's dense cubic storage provides greater capacity—34,000 bin positions versus 24,500 previously. The WES is configured to prioritize embroidery needs, dedicating ports to select items required within the next four production hours.

"Our biggest goal was eliminating picking bottlenecks to significantly improve efficiency across decoration and fulfillment operations," Freet emphasized. "Faster turnarounds for customers is the long-term objective. With years of growth capacity built into this system, we can maintain ultra-fast deliveries while continuing to optimize other operations."

Service Level Breakthrough

While labor reduction was significant, Sampt clarifies the primary driver wasn't headcount reduction but operational fluidity—reallocating staff to value-added roles like embroidery while achieving faster cycle times. The solution proved particularly crucial for maintaining service levels across all sales channels during peak periods.

In today's unforgiving retail environment, success requires both compelling products and flawless omnichannel fulfillment. As both Sampt and Freet affirm, Cutter & Buck's automation investment ultimately elevates service standards across all channels—transcending mere cost-per-pick metrics to deliver what modern customers demand: speed, accuracy, and reliability.