Picture this scenario unfolding daily in your distribution center: mountains of paper timecards, overtime request forms flying everywhere, manual scheduling struggling to keep pace with fluctuating order volumes, and the monthly payroll calculation becoming an accounting nightmare. This isn't hypothetical—it's the "labor cost black hole" plaguing countless logistics operations. The solution? Implementing a Labor Management System (LMS).

While many logistics managers initially viewed LMS as another costly IT investment, mounting success stories demonstrate how these systems deliver measurable efficiency gains at relatively low implementation costs. This examination explores LMS's value proposition, practical applications, and emerging trends to help operations optimize their workforce investment.

I. LMS: The Logistics Sector's Efficiency Multiplier

Gartner defines LMS as systems providing workforce productivity reporting and planning capabilities. These solutions analyze labor requirements for specific workloads and standard completion times per work unit, enabling precision workforce management.

Core LMS functionalities include:

- Demand forecasting: Leveraging historical data to predict facility throughput and schedule regular staff, overtime, and temporary labor to accommodate seasonal fluctuations.

- Performance monitoring: Measuring and reporting individual, team, and facility performance against predefined benchmarks to identify bottlenecks.

- Shift optimization: Generating ideal schedules by analyzing employee skills, workload distribution, and cost efficiency.

- Attendance automation: Digitally tracking employee presence to reduce manual entry errors.

- Compliance assurance: Maintaining training records and certification tracking to meet regulatory requirements.

These capabilities help logistics operations achieve:

- 15-30% labor cost reductions through minimized unnecessary overtime and improved productivity

- 20-40% throughput increases via optimized resource allocation

- Enhanced employee satisfaction through fair scheduling and performance evaluation

- Data-driven decision making with comprehensive analytics

II. Practical Applications: Where LMS Delivers Value

LMS solutions prove effective across logistics operations:

- Warehousing: Optimizing staffing for receiving, picking, packing, and shipping operations

- Transportation: Improving driver scheduling, route planning, and vehicle deployment

- Last-mile delivery: Enhancing courier scheduling and package routing efficiency

- Customer service: Streamlining agent scheduling and ticket resolution workflows

Successful implementation requires:

- Clear operational objectives before deployment

- Careful vendor selection matching organizational needs

- Comprehensive employee training programs

- Continuous system performance evaluation

III. Industry Perspective: LMS as Process Catalyst

Norman Saenz, Managing Director at St. Onge Company, observes growing logistics interest in LMS as organizations witness peers achieving tangible benefits. "They're hearing productivity improvement stories where software solutions delivered relatively low-cost benefits," Saenz notes.

He emphasizes LMS's unique role as a process improvement catalyst rather than mere software. "It facilitates examination of organizational audit methods, standards, and preferred procedures before implementation," Saenz explains. The labor standard analysis process itself yields operational insights regardless of eventual system deployment.

IV. Market Evolution: New Opportunities Emerging

The LMS market is experiencing renewed growth as logistics operations face intensifying competition and technological advancements expand system capabilities. The landscape includes specialized vendors like Kronos and Spalding Software alongside enterprise solution providers offering workforce management modules.

"When major vendors focus on comprehensive installations rather than $100,000 LMS projects, it creates space for specialized providers," Saenz notes, suggesting opportunities for innovative workforce management solutions.

V. Overcoming Implementation Barriers

John Frehse, CorePractice Management Partner, identifies cost justification and workforce disruption concerns as primary LMS adoption obstacles. "Even with proven ROI, organizations hesitate to alter established labor practices," Frehse observes.

However, persistent budget pressures are changing perspectives. "With operations needing 5-10% annual cost reductions, more facilities are embracing workforce management technology," Frehse notes. Modern LMS solutions now offer real-time productivity monitoring, enabling immediate corrective actions rather than weekly reviews.

VI. Future Directions: Emerging LMS Capabilities

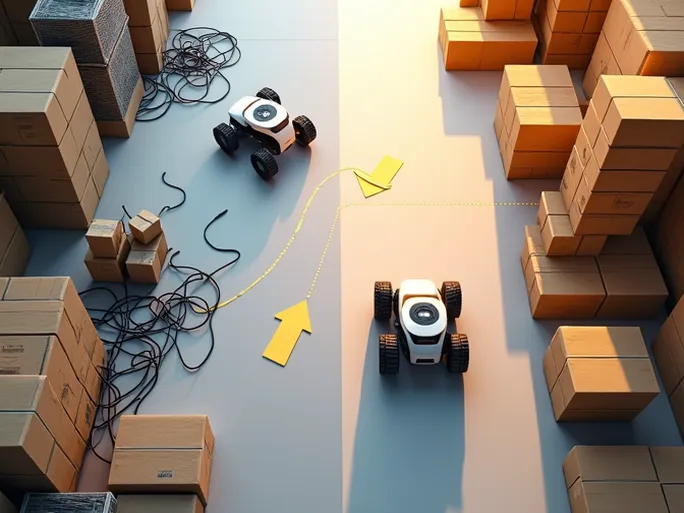

Next-generation LMS solutions incorporate mobile functionality for floor supervisors and explore location tracking technologies. "Worker position management represents the final frontier in distribution center labor optimization," Frehse states, acknowledging privacy considerations while emphasizing operational benefits like travel time reduction and pick path optimization.

As workforce management technology continues evolving alongside logistics operations' changing needs, LMS solutions will play an increasingly vital role in maintaining competitive efficiency.