For fruit enthusiasts seeking an unparalleled taste experience, the journey from orchard to table has never been more technologically advanced. Mount Adams Fruit, a pioneering force in fresh produce distribution, is transforming the industry through cutting-edge automation solutions that ensure optimal quality and freshness.

Redefining Fresh Fruit Distribution

Mount Adams Fruit has established itself as an innovator in fruit distribution, combining agricultural expertise with technological advancements. The company's highly automated distribution center represents a significant departure from traditional produce handling methods, addressing long-standing challenges of efficiency, waste reduction, and product traceability.

Intelligent Production Planning

Before fruit leaves the orchard, Mount Adams Fruit's smart systems begin their work. Advanced predictive analytics incorporate historical data, weather patterns, and grower communications to forecast yields, ripeness levels, and arrival times with remarkable accuracy. This forward-looking approach enables optimal resource allocation and dynamic response to market fluctuations.

Precision Temperature Control and Grading

Upon harvest, produce immediately enters climate-controlled storage environments that meticulously regulate temperature, humidity, and atmospheric composition. These specialized chambers significantly extend shelf life while maintaining quality. The company's sophisticated grading system further categorizes fruit by size, color, shape, and blemishes to meet diverse market specifications.

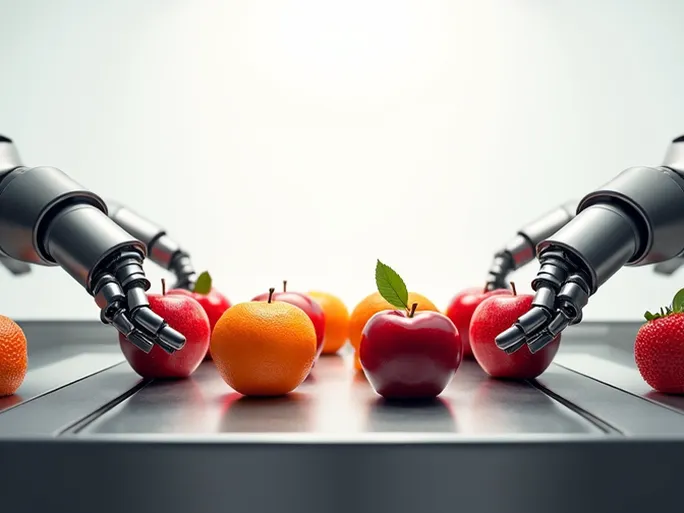

AI-Enhanced Quality Inspection

Mount Adams Fruit employs computer vision systems with artificial intelligence capabilities to perform comprehensive quality assessments. These advanced scanners detect both surface imperfections and internal defects with greater precision than human inspectors. The AI system also determines optimal packaging configurations, minimizing waste while maximizing efficiency.

Hybrid Packaging Approach

While automation handles most packaging processes, delicate fruits receive manual attention to prevent damage. Each packaged container receives a unique identification code containing detailed product information, enabling complete traceability from grower to consumer.

Automated Storage and Retrieval

The company's Automated Storage and Retrieval System (AS/RS) functions as a highly efficient "fruit library," with robotic systems managing inventory movement. Key features include:

- Secondary quality control stations for additional inspection

- Six robotic palletizers handling standard packaging

- Automated stretch wrapping with protective corner boards

- Multi-entry receiving stations for different product types

- Intelligent storage allocation based on pallet dimensions

Flexible Processing Capabilities

The system accommodates various post-storage requirements, including repackaging into retail-ready formats or additional quality verification. When orders are placed, the AS/RS retrieves pallets and stages them for shipment through an automated conveyor system.

Operational Benefits

Mount Adams Fruit's automation investments have yielded measurable improvements:

- Enhanced processing speed and reduced time-to-market

- Consistent quality preservation throughout the supply chain

- Complete product traceability from origin to destination

- Reduced labor costs and minimized product waste

This technological transformation demonstrates how automation can address longstanding industry challenges while meeting evolving consumer expectations for quality and transparency in fresh produce.