In the vast ocean of international trade, shipping containers serve as reliable vessels carrying goods across continents. Among them, the 20-foot container (20GP) stands out as one of the most common choices due to its versatile applicability. But how well do you understand its specifications? What's its actual loading capacity? And what details require special attention? This comprehensive guide examines the key aspects of 20-foot containers including dimensions, volume calculations, and weight limitations to help optimize your shipping operations.

Standard Dimensions and Volume of 20-Foot Containers

The 20-foot container, commonly referred to as 20GP (General Purpose), is a standardized metal box designed for multimodal transportation including sea and land shipping. Its specifications directly impact loading efficiency and shipping costs.

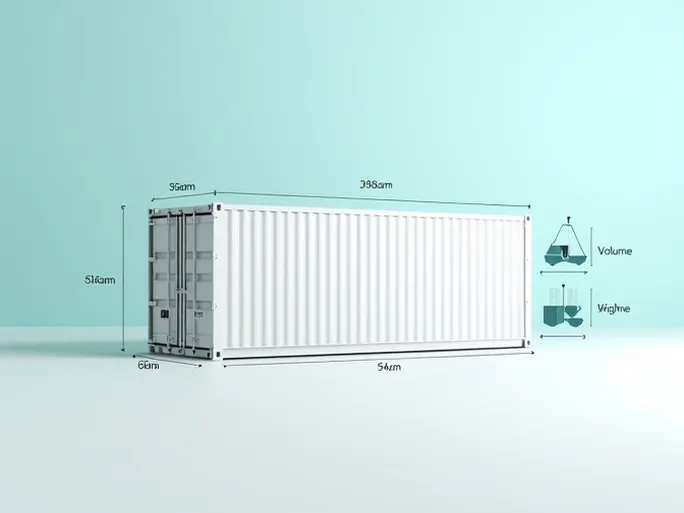

External Dimensions:

- Length: 20 feet (approximately 6.096 meters)

- Width: 8 feet (approximately 2.438 meters)

- Height: 8 feet 6 inches (approximately 2.591 meters)

Internal Dimensions:

- Length: Approximately 5.898 meters

- Width: Approximately 2.352 meters

- Height: Approximately 2.393 meters

The internal dimensions are slightly smaller than external measurements due to the container's structural components. For accurate loading calculations, always refer to internal dimensions.

Volume Calculation:

The theoretical capacity based on internal dimensions is:

Volume = Length × Width × Height ≈ 5.898m × 2.352m × 2.393m ≈ 33.1 cubic meters

However, practical loading capacity typically ranges between 24-28 cubic meters due to packaging shapes, loading patterns, and necessary safety gaps. Uniform, tightly-packed goods may approach 28 cubic meters, while irregularly shaped items requiring spacing might only utilize about 24 cubic meters.

Weight Limitations of 20-Foot Containers

Beyond volume considerations, weight restrictions are crucial for safe and compliant shipping operations.

Key Weight Parameters:

- Maximum Gross Weight: Combined weight of container and cargo (typically 21.6 metric tons/21,600kg for 20GP containers, as marked on container doors)

- Tare Weight: Empty container weight (approximately 2.2 metric tons)

- Maximum Payload: Calculated as Maximum Gross Weight minus Tare Weight (typically about 19.4 metric tons)

It's essential to ensure cargo weight never exceeds the maximum payload. High-density goods might reach weight limits before filling the container's volume. Regional weight regulations may vary and should be verified before shipping.

Factors Affecting Loading Capacity

Several variables influence actual loading capacity:

- Packaging: Compact, uniform packaging maximizes space utilization while irregular shapes create wasted space

- Item Dimensions: Large items may require special arrangements or prove incompatible with container dimensions

- Weight Distribution: Heavy items must be properly positioned to maintain container balance

- Special Requirements: Temperature control, humidity management or safety measures may reduce usable space

- Loading Expertise: Skilled handlers optimize space utilization through strategic placement and securement

Optimizing Container Loading Efficiency

To maximize space utilization and minimize shipping costs:

- Use standardized, space-efficient packaging with minimal void spaces

- Develop detailed loading plans considering all dimensional and weight factors

- Utilize appropriate loading equipment (forklifts, cranes) for heavy items

- Implement professional securing methods (straps, braces) to prevent shifting

- Train loading personnel in space optimization techniques

Specialized 20-Foot Container Variants

Beyond standard 20GP containers, specialized versions accommodate unique cargo requirements:

- Open-Top Containers (20OT): Removable tops facilitate loading of oversized items

- Flat Rack Containers (20FR): Open-sided designs for exceptionally large or heavy cargo

- Refrigerated Containers (20RF): Temperature-controlled for perishable goods

- Tank Containers (20TK): Designed for liquid or gas transportation

Conclusion

The 20-foot container remains a fundamental tool in global trade. Understanding its specifications, limitations, and optimization strategies enables businesses to maximize shipping efficiency while ensuring cargo safety. Proper planning and execution of loading operations can significantly impact transportation economics and supply chain performance.