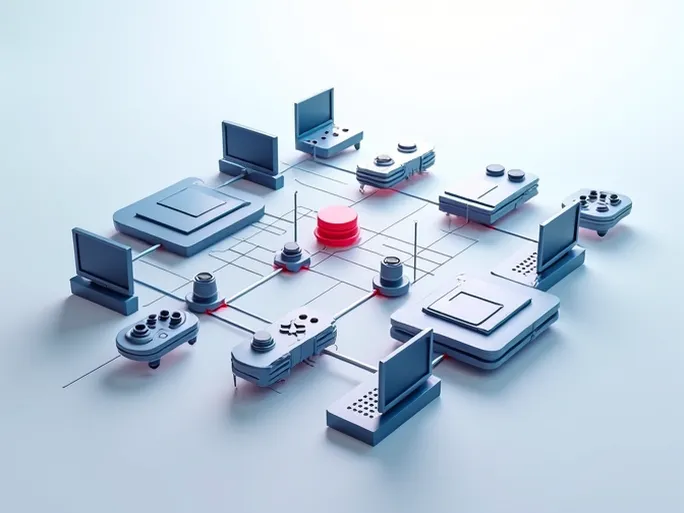

The Nintendo Switch, an innovative gaming console that blends handheld portability with home console performance, has captivated global audiences since its 2017 launch. However, its remarkable success has been shadowed by persistent supply shortages—not a deliberate marketing tactic, but rather a complex supply chain battle hidden behind the product's popularity. This analysis examines the Switch's supply chain challenges, their underlying causes, and Nintendo's strategic options.

The Switch Phenomenon: Innovation Meets Opportunity

Before delving into supply issues, we must acknowledge the Switch's groundbreaking design. More than simply combining portable and home console features, the Switch created an entirely new gaming paradigm. Players can enjoy immersive television gameplay or take their experience anywhere—perfectly aligning with modern gamers' fragmented play patterns.

Complementing its innovative hardware, the Switch boasts an exceptional game library. Exclusive titles like The Legend of Zelda: Breath of the Wild , Super Mario Odyssey , and Animal Crossing: New Horizons have driven both console adoption and Nintendo's profitability. Yet this success story continues to be hampered by chronic shortages rooted in supply chain vulnerabilities.

Component Shortages: The Switch's Achilles' Heel

The core challenge lies in semiconductor and display component shortages. Nintendo faces intense competition for these parts from smartphone manufacturers, data center operators, and automotive electronics firms—all with greater purchasing power.

1. Surging Global Electronics Demand

Explosive growth across consumer electronics sectors has created unprecedented demand for critical components, stretching supply chains thin while driving up prices.

2. Limited Supplier Capacity

Key Switch components come from specialized suppliers operating at maximum capacity. For instance, Toshiba—a vital Nintendo partner—simultaneously serves higher-volume clients in mobile and enterprise markets, leaving Nintendo competing for residual capacity.

3. Competitive Disadvantage

Compared to tech giants like Apple with massive order volumes and pricing leverage, Nintendo's smaller-scale console business struggles to secure priority allocation.

4. Patent Constraints

Certain proprietary components remain exclusively controlled by suppliers, forcing Nintendo to accept their production schedules rather than dictate terms—a precarious dependency.

Strategic Dilemma: Raise Prices or Face Shortages?

Nintendo's sales and operations planning (S&OP) faces difficult trade-offs:

1. Increasing Orders: Cost Inflation Risk

Securing more components would likely require paying premium prices, potentially forcing Nintendo to raise the Switch's $299 MSRP—a dangerous move in the price-sensitive console market.

2. Maintaining Current Orders: Perpetual Shortages

Sticking with existing procurement levels sustains inventory problems, frustrating consumers and potentially driving them toward PlayStation or Xbox alternatives.

3. Core S&OP Challenge

Balancing adequate supply against cost control demands precise demand forecasting and supplier coordination—areas where Nintendo appears to be struggling.

Potential Solutions: Diversification and Collaboration

To mitigate single-supplier risks, Nintendo could pursue several strategies:

1. Supply Chain Diversification

Developing alternative component sources would reduce dependence on any single vendor, though qualifying new suppliers requires significant time and quality validation.

2. Strategic Supplier Partnerships

Deeper collaboration with key suppliers like Toshiba could yield more favorable terms. Joint development of customized components might also improve supply stability.

3. Vertical Integration (Long-Term)

Acquiring or investing in component manufacturers would grant Nintendo greater control, though this capital-intensive approach carries substantial risk.

Long-Term Implications: Brand and Market Position

Prolonged shortages risk eroding Nintendo's brand equity and market share:

1. Brand Erosion

Chronic unavailability may frustrate consumers, damaging Nintendo's reputation for accessibility and reliability.

2. Market Share Loss

Unable to meet demand, Nintendo effectively cedes potential sales to competitors during critical console lifecycle periods.

3. Secondary Market Issues

Shortages inevitably fuel scalping markets where consoles sell at inflated prices—further alienating legitimate customers.

Broader Industry Lessons

The Switch's supply woes reflect systemic challenges facing global electronics manufacturing:

1. Agile Supply Networks

Companies must develop more responsive supply chains capable of adapting to demand volatility and disruption.

2. Risk Mitigation

Comprehensive supply chain risk assessments should identify single points of failure, whether geographic, logistical, or supplier-specific.

3. Digital Transformation

Advanced supply chain technologies—from IoT tracking to predictive analytics—can enhance visibility and responsiveness.

Strategic Crossroads

Nintendo's predicament represents more than temporary logistics issues—it's a fundamental test of strategic prioritization:

1. Short-Term vs. Long-Term

While scarcity can create artificial demand, prolonged shortages may permanently shift consumer loyalties.

2. Brand Loyalty Economics

Customer retention and lifetime value depend on consistent product availability and positive purchase experiences.

3. Competitive Vulnerability

Supply chain weaknesses become strategic liabilities when competitors can reliably meet market demand.

Conclusion: Crisis and Opportunity

The Switch supply chain crisis presents both peril and possibility for Nintendo. Successfully addressing these challenges could strengthen its market position, while failure risks ceding hard-won advantages. How Nintendo navigates this complex situation will significantly influence its future in the increasingly competitive gaming hardware landscape.